When it comes to woodworking, a jointer is one of those tools that can really make a difference. If you’re looking to create flat surfaces on your lumber, this is the go-to equipment. Jointers take rough, uneven wood and smooth it out, making it easier to work with later on. Whether you’re building furniture or cabinets, knowing how to use a jointer is essential.

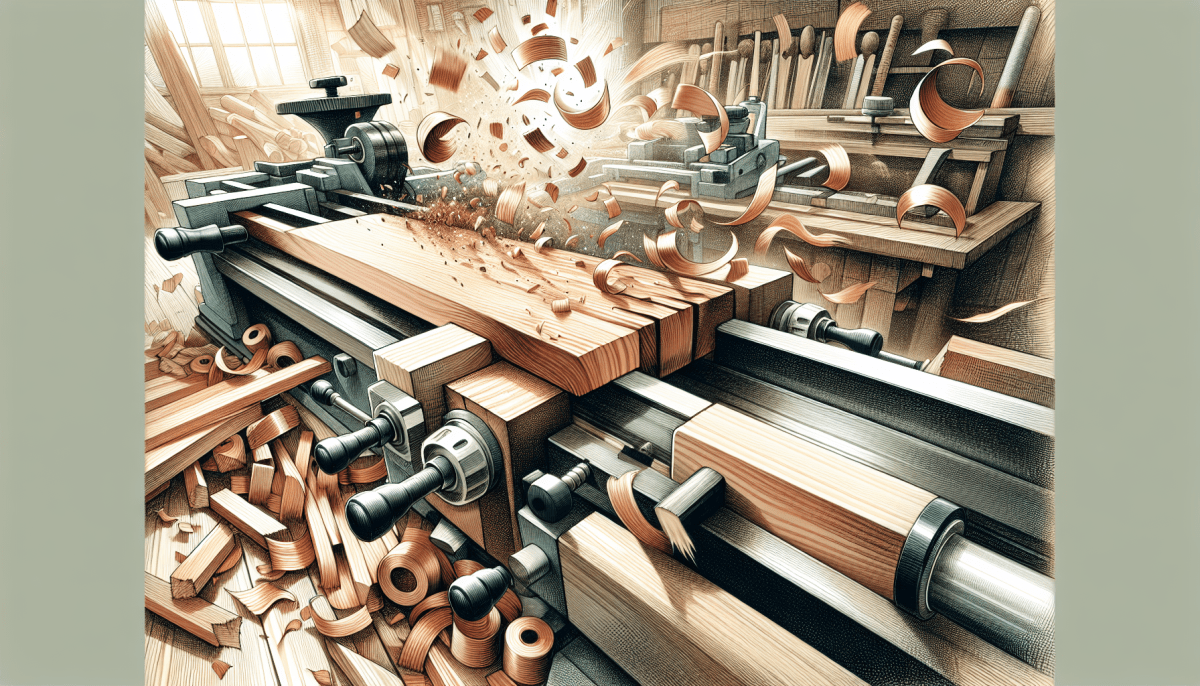

So, how does a jointer actually work? It uses a set of sharp blades rotating at high speed to shave off thin layers from the wood. You simply feed the wood through the machine, and voila – you have a nice, flat edge ready for your next project. Most jointers come with infeed and outfeed tables, ensuring that the wood remains supported as it passes through.

Choosing the right jointer for your needs is important. Here are a few factors to keep in mind:

Also, don’t overlook safety features. Good jointers come with guards to keep your hands safe while you work. Taking the time to learn about your jointer and practicing safe operating techniques will help you make the most out of this handy tool. Whether you’re a beginner or have a few projects under your belt, a jointer can really add that professional touch to your woodworking creations.

Key Features to Look For

When shopping for a woodworking jointer, there are a few key features that can really make or break your woodworking experience. Here’s what to keep an eye out for:

Pay close attention to these features while browsing. They’ll help ensure that you choose a jointer that meets your needs and helps you create amazing woodwork projects!

How to Choose the Right Jointer

Choosing the right jointer can feel a bit overwhelming at first, but breaking it down into a few key factors makes it much easier. First up, consider the size of the jointer. If you’re working with larger boards, a wider jointer (around 8 inches) will give you better results. But if your projects are smaller, a 6-inch model could be just fine and more budget-friendly.

Next, think about the motor power. More powerful motors can handle tougher woods and larger cuts without struggling. A 1 to 2 horsepower motor is usually a solid choice for most home woodworkers, helping you get through various materials smoothly without slowing down.

Don’t forget the construction quality! Look for a jointer that feels sturdy and well-built. A cast iron base, for instance, helps reduce vibration, providing more accurate jointing. Check reviews for user feedback about durability before making a decision.

Lastly, ease of use is vital. Features like adjustable tables, easy-to-reach controls, and a clear dust collection system make a jointer much more enjoyable to work with. Think about what will make your woodworking experience smoother and choose accordingly.

Top Tips for Using Your Jointer

Getting the most out of your jointer can really elevate your woodworking projects. Here are some top tips to help you use your jointer effectively:

Following these simple tips can turn your jointer into a powerhouse tool in your workshop. The more you use it, the more confident you'll become, and before you know it, you’ll be producing beautifully flattened boards for your next project!